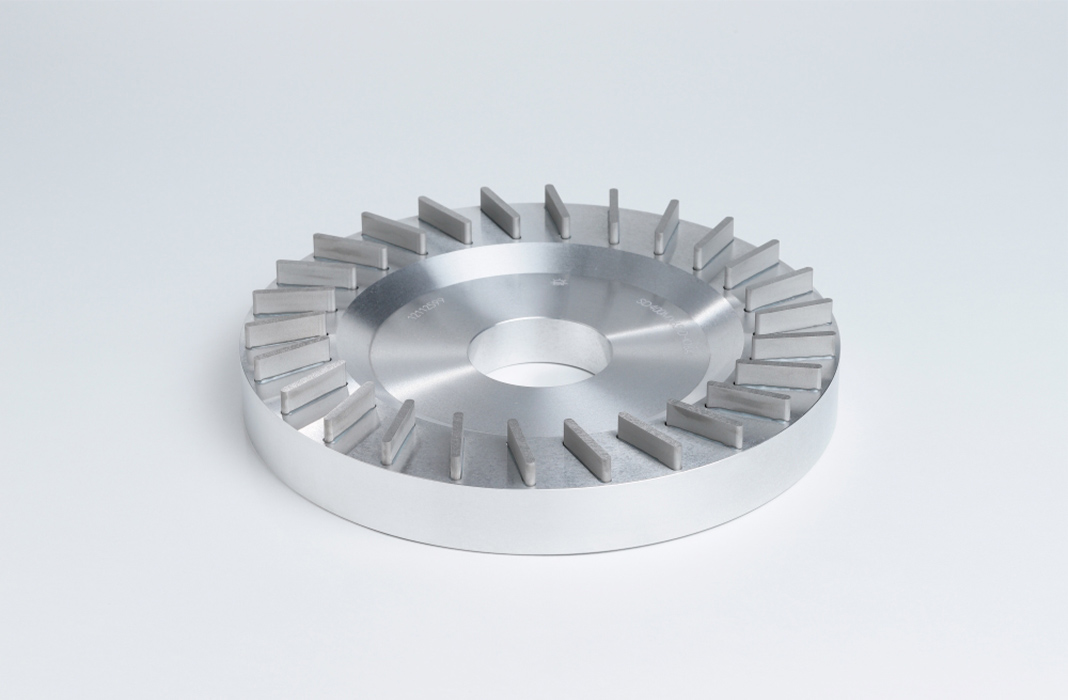

Diamond wheel for grinding SiC surfaces "M-cloud"

Metal bond wheels for surface grinding of wafers such as SiC and GaN. The ultra-porous structure realizes fine grain grinding, which could not be applied with conventional metal bond wheels, and has excellent sharpness and wear resistance compared to vitrified bond wheels of the same particle size.

Electroplated Wheels for Form Grinding "SUN CREST2"

Electroplated wheels are equipped with thread-like irregularities on the outer circumferential surface and are specialized for processing that requires sharpness.

High-efficiency Metal Bond for Difficult-to-cut Materials "SUNCREA"

SUNCREA contributes to improving processing efficiency and reducing costs in hard and brittle materials such as sapphire, carbide, and ceramics, hard magnetic materials such as ferrite and neodymium iron, and iron-based materials such as sintered parts.

Super-Porous Metal Bond Wheels "AEROMETAL"

Features

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with Electroplated truer is possible (limited to CBN ).

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with Electroplated truer is possible (limited to CBN ).

Brazed Diamond Tools "STAR LAYER"

Brazed Diamond Tools "STAR LAYER" (Our registered trademark name: STAR LAYER) are tools that have a structure ㏌ which diamond abrasive grains are fixed ㏌ a single layer on a precisely machined base metal using brazing material. In contrast to electroplated tools, the abrasive grains are firmly bonded to the base metal, giving them strong retention strength and a large protrusion. In addition, the arrangement and spacing of the abrasive grains can be adjusted, and by taking advantage of the improved sharpness and the characteristics of being less prone to clogging, it can be used for a variety of applications and tool shapes (Diamond Core Drills, Diamond Cutters, Diamond Wheels, etc.) from rough processing to finishing processing.

Electroplated Wheels "Ceramate Series"

Wheel with electroplated shaft that is specialized for machining ceramics used in semiconductor manufacturing equipment parts, etc., and provides stable sharpness with high accuracy, high efficiency, and long life. The Ceramate Drill dedicated to the center-through type with high cooling effect and revolutionary machining speed for highly efficient machining, the Ceramate End Mill as a grooving tool, the Ceramate Tap as a threading tool capable of machining JIS Class 2 precision (M3 to M12) screws with half the number of threads to reduce tool load, and the Ceramate High Speed Cutting Tool for high efficiency contour cutting. The Ceramate Contouring is a high-efficiency contouring tool that enables high-speed feed machining.

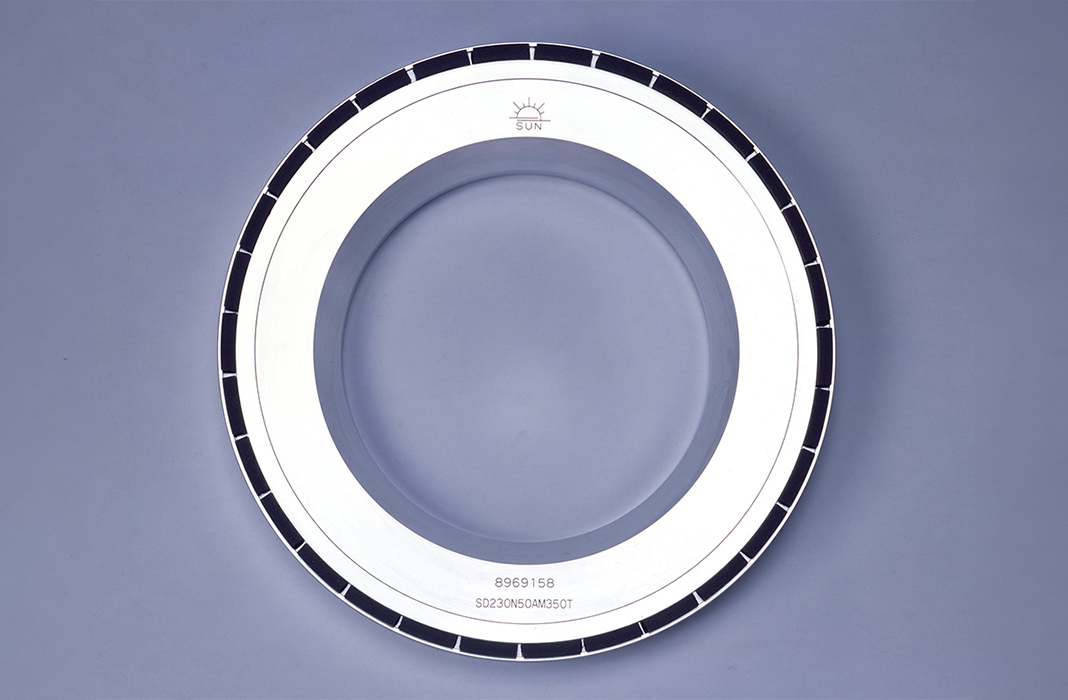

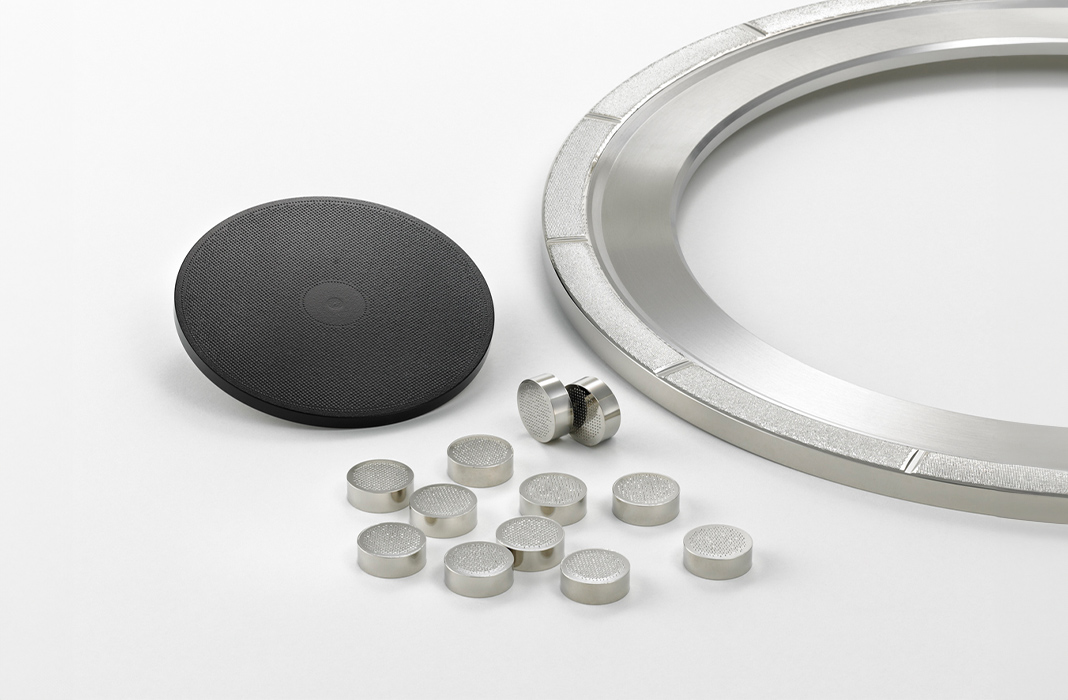

CMP Conditioners

In the manufacturing process of semiconductor devices and wafers, the demand for planarization is increasing year by year as wiring becomes finer and more multilayered. In the CMP process, which is used as a planarization technology, the conditioning of polishing pads plays an important role in stabilizing polishing characteristics, and we have been providing high-quality, highly reliable conditioners for over 25 years. We continue to contribute to the stabilization of the CMP process, offering conditioners in a variety of shapes and specifications to meet diverse needs.

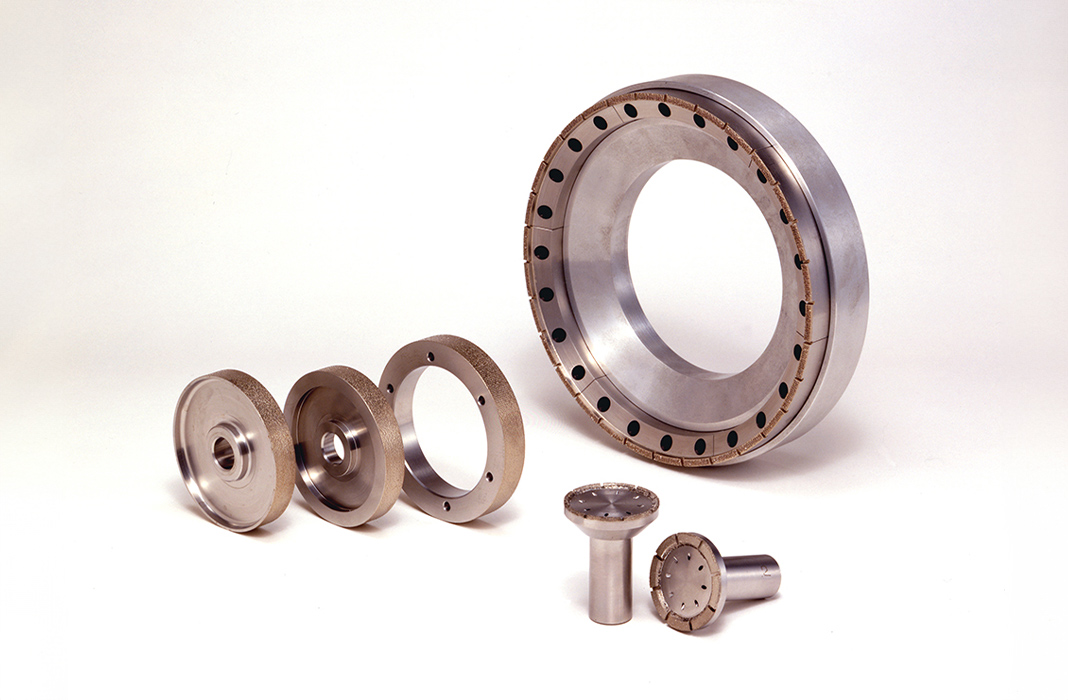

Notch Grinding Wheels

Small-diameter formed wheels are used to finish the notches of large-diameter wafers. Our notch grinding wheels maintain the run out accuracy of diamonds to the shank, and realize a favorable wafer circumference. As with our edge grinding wheels, we are able to provide a wide variety of specifications, including single-grooved wheels, multi-grooved wheels, and wheels for both rough and finish grinding.

Diamond Grinding Wheels for Chamfering

Metal bond wheels and resin bond wheels are used in edge grinding on the outer circumference of silicon wafers, which requires uniform sharpness in addition to precision accuracy in the shape of the wheel and abrasion resistance. We are able to provide a wide variety of specifications, including single grooved wheels, multi-grooved wheels, and wheels for both rough and finish grinding.

Diamond Wheels for Peripheral Grinding, Orientation Flat Processing

Diamond metal wheels and diamond resin wheels are used for grinding silicon ingots for solar cells and semiconductors. Based on our experience in various fields, we offer wheels that meet the needs of our customers and the machines they own.

Cutter with Steel Core

Cutters with a metal base are available in "multi-cutters" and "single-blade types. Multi-cutters can cut and groove by combining multiple cutters with specifications suitable for the work material. Our unique technologies such as cutting edge shape, pitch accuracy, and accumulation accuracy realize high machining quality. The single-blade type is a cutter with a diamond or CBN abrasive grain layer formed on the periphery of the steel steel core. Electroplated, metal, or resin can be selected for the bond, and the cutting edge shape (V-shape, R-shape) and steel core shape (all relief, under-neck relief) can also be selected according to requirements.

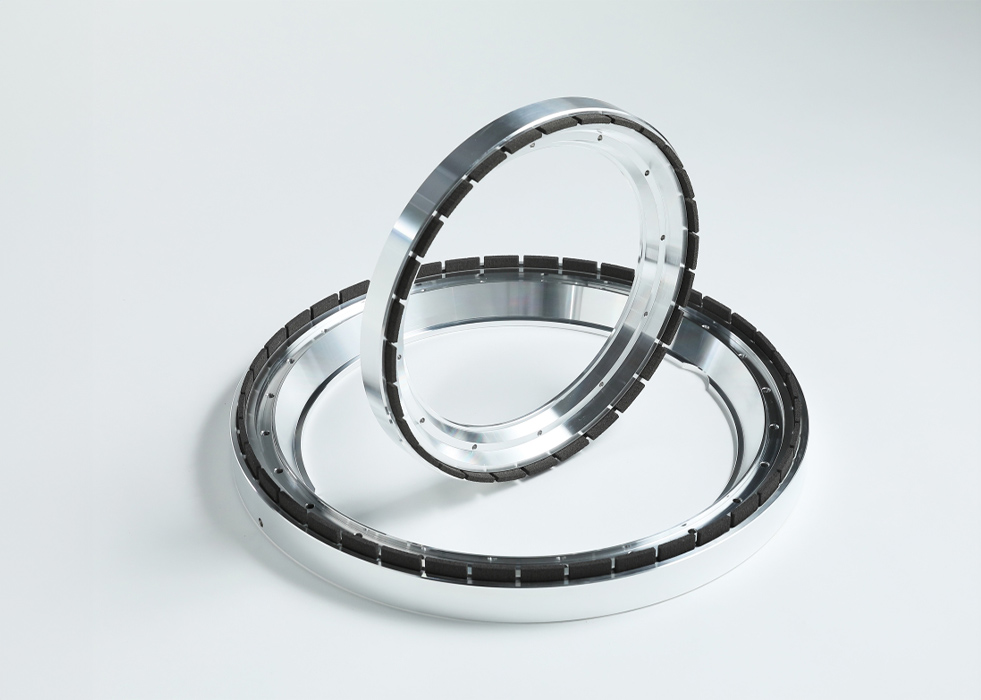

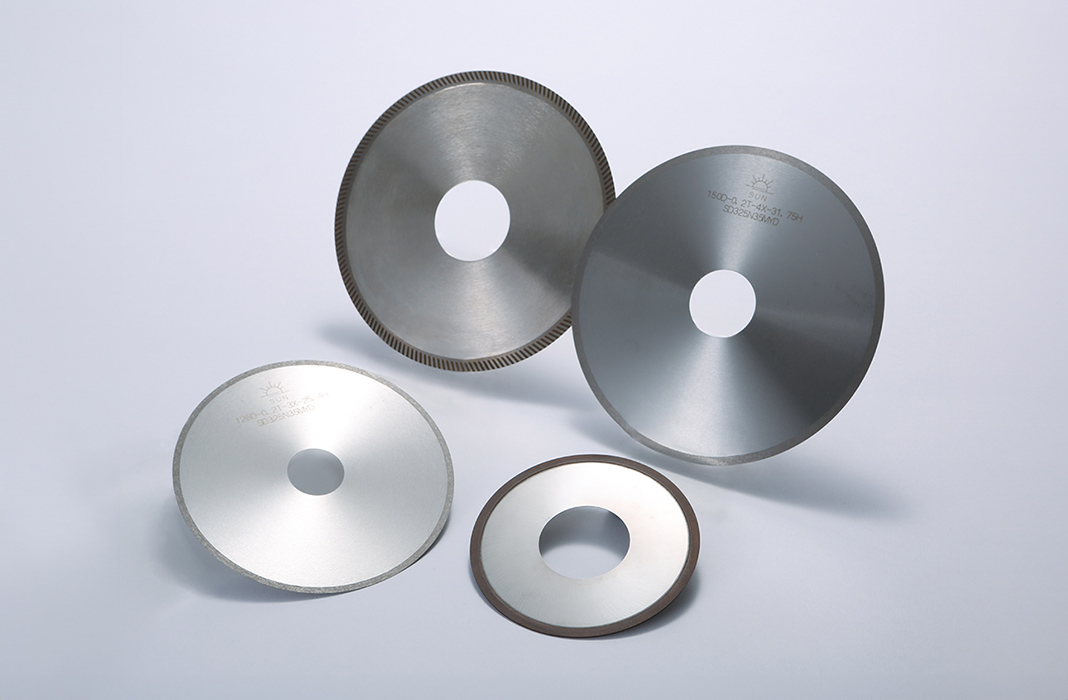

Dicing Blade

Dicing blades are available in "hub type" and "ring type." The hub type is mainly used for dicing silicon and compound wafers for semiconductors. The hub type is mainly used for dicing silicon and compound wafers for semiconductors. The aluminum base and nickel diamond layer are combined into a single unit, making it easy to handle. The ring type can be used for a wide range of cutting and grooving of various PKG and electronic component materials in addition to semiconductor silicon and compound wafers. Three types of bond can be selected: electroformed, metal, and resin. The electroformed bond can produce an ultra-thin blade with a thickness of 15 μm. The resin bond is often used for cutting glass, ceramics, QFN, and other PKGs where chipping and cutting resistance must be suppressed. Metal bond can be selected from a wide range of bond lineups, from high rigidity types comparable to electroforming to types with excellent cutting performance, to suit various work materials.