CBN Electroplated Wheels for High-Precision Grinding

CBN electroplated wheel suitable for machining high-precision gross shapes by truing after Electroplated. No adjustment on the machine is required, and Ra 0.8μm or less and shape accuracy of ±0.005mm can be achieved.

High-efficiency Metal Bond for Difficult-to-cut Materials "SUNCREA"

SUNCREA contributes to improving processing efficiency and reducing costs in hard and brittle materials such as sapphire, carbide, and ceramics, hard magnetic materials such as ferrite and neodymium iron, and iron-based materials such as sintered parts.

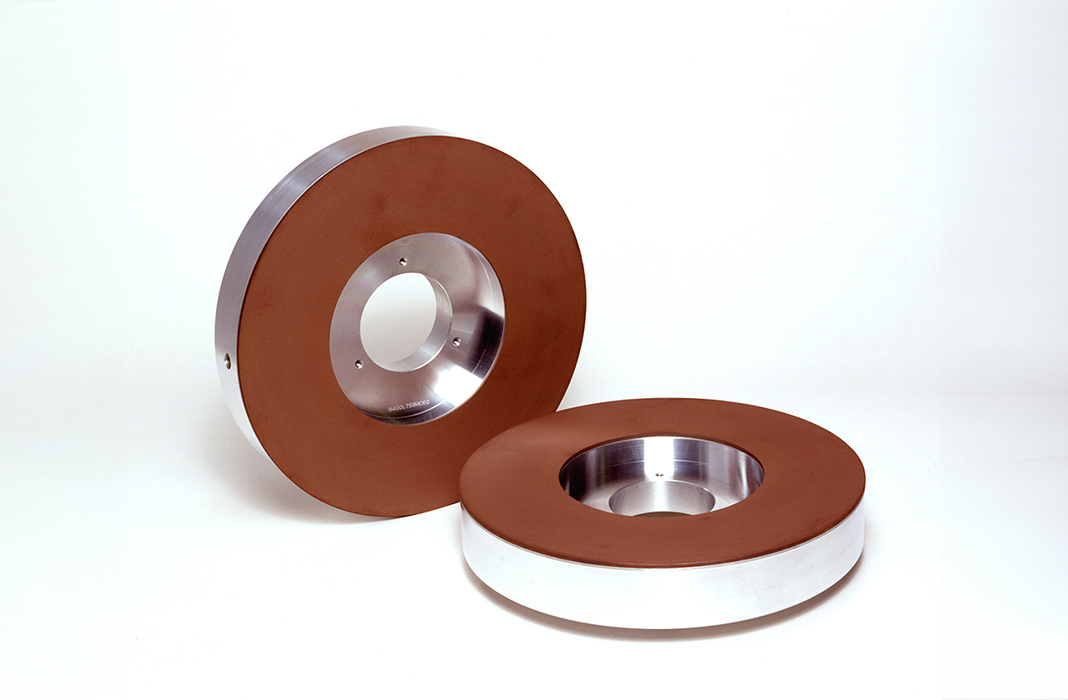

Super-Porous Metal Bond Wheels "AEROMETAL"

Features

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with Electroplated truer is possible (limited to CBN ).

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with Electroplated truer is possible (limited to CBN ).

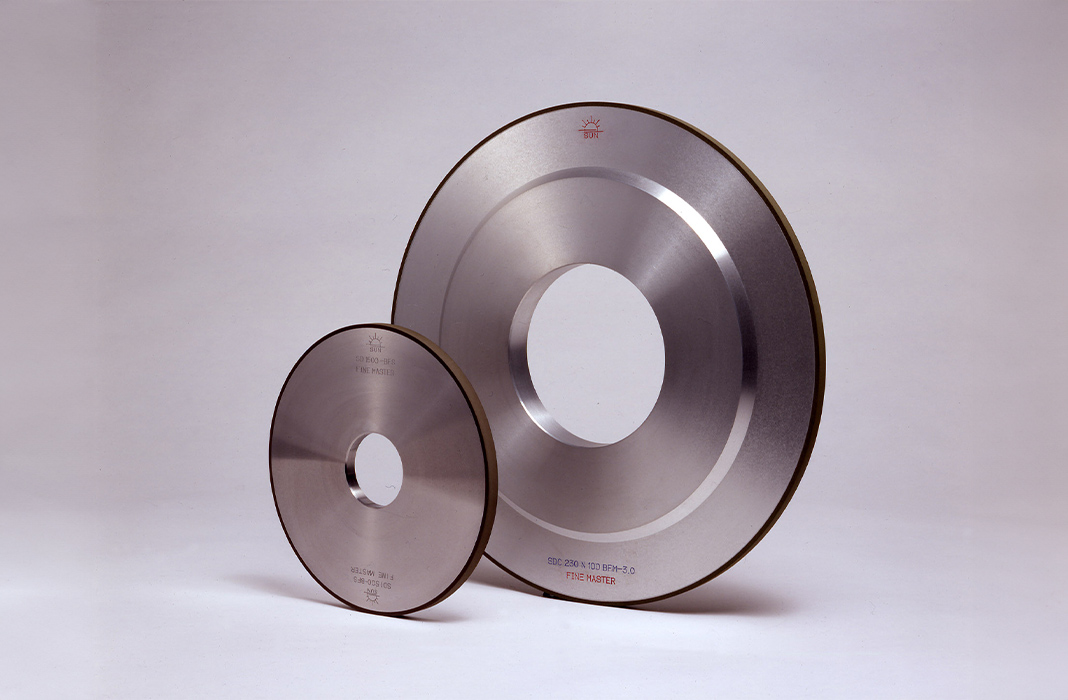

Simultaneous Grinding & Mirror Fishing "FINE MASTER"

The FINE MASTER series is a wheel that uses "BFM bond" for simultaneous grinding that realizes simultaneous grinding of heterogeneous composite materials such as tungsten carbide and steel materials with high efficiency and high precision, and "BFS bond" for mirror finishing, which realizes mirror grinding of tungsten carbide, steel materials, ceramics, etc. with high efficiency and high precision.

Double Disc Centerless Grinding Wheels "TafRa"

TafRa wheels are Products with higher abrasive grain retention compared to exciting products. In Double disc grinding and centerless grinding, where the spontaneous action of abrasive grains is unlikely to occur, The abrasive grains remain for a long time without falling off, so that the sharpness is maintained and the dress interval is extended. As with existing products, it can be applications with WA dresses and X-POWER dresses.

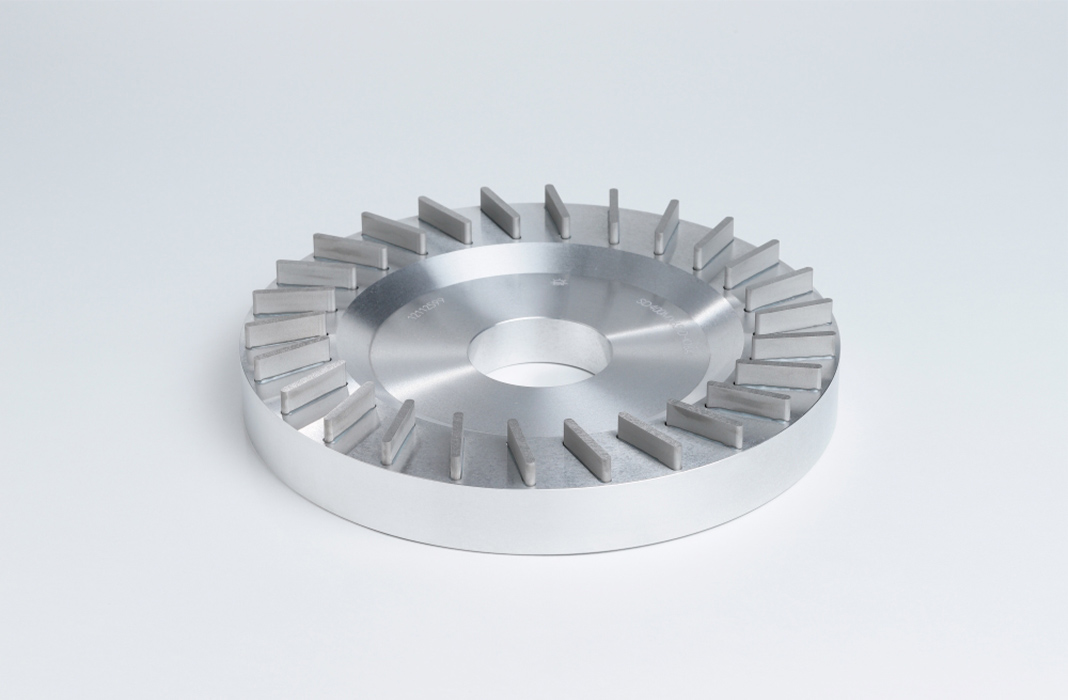

CBN Vitrified Bond Wheel

CBNVitrified bond wheels are manufactured in a variety of sizes, from small-diameter wheels of φ10 mm or less to large-diameter wheels of φ1000 mm, and are widely used in a wide range of applications, including the machining of various automobile parts and the internal grinding of bearings. We also support various applications such as form grinding wheels for angular grinding, centerless wheels, and double-disc wheels with hexagonal pellets.

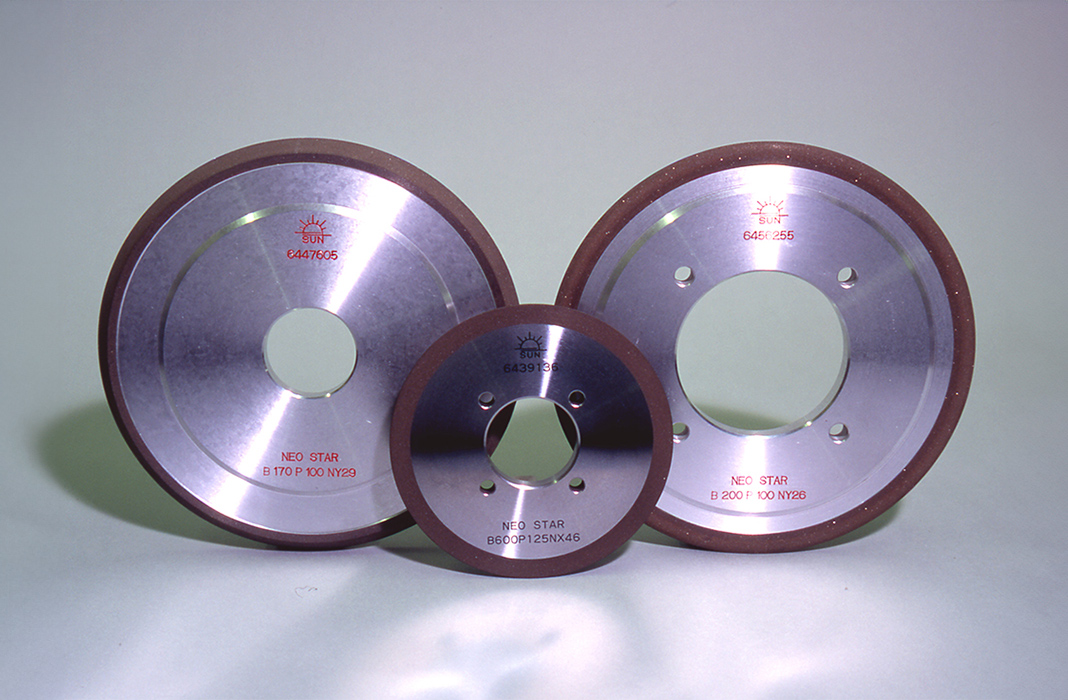

CBN POLYX Wheel for Ferrous Materials "NEO STAR"

NEO STAR wheels are bonded with polyimide resin, which has excellent heat resistance, tensile strength, and elasticity. It can be used for grinding that requires long-time shape retention, heavy-duty grinding, creep-feed grinding, efficient grinding of high-hardness steel (HRC67 higher), and grinding of relatively low-hardness steel (HRC40-50 ) that requires long life.

PCD/PCBN Reamer

With stable quality based on control of outer diameter dimension and runout accuracy, which are the key elements of reamers, we can design for high precision requirements such as machined surface roughness, roundness, and coaxiality, as well as high-speed feed. We have a large lineup of products, from standard specifications to value-added specifications, to meet our customers' needs.

Monocrystalline DiaBite/Endmill "SUNBRIGHT"

"SUNBRIGHT" is a monocrystalline diamond cutting tool for ultra-precision cutting.

The sharp cutting edges and nano-order level contouring accuracy have been established through high-precision machining technology.

It can be used for various lens products, lens molds, and mirror finishing of non-ferrous metal products.

The sharp cutting edges and nano-order level contouring accuracy have been established through high-precision machining technology.

It can be used for various lens products, lens molds, and mirror finishing of non-ferrous metal products.

Cutter with Steel Core

Cutters with a metal base are available in "multi-cutters" and "single-blade types. Multi-cutters can cut and groove by combining multiple cutters with specifications suitable for the work material. Our unique technologies such as cutting edge shape, pitch accuracy, and accumulation accuracy realize high machining quality. The single-blade type is a cutter with a diamond or CBN abrasive grain layer formed on the periphery of the steel steel core. Electroplated, metal, or resin can be selected for the bond, and the cutting edge shape (V-shape, R-shape) and steel core shape (all relief, under-neck relief) can also be selected according to requirements.

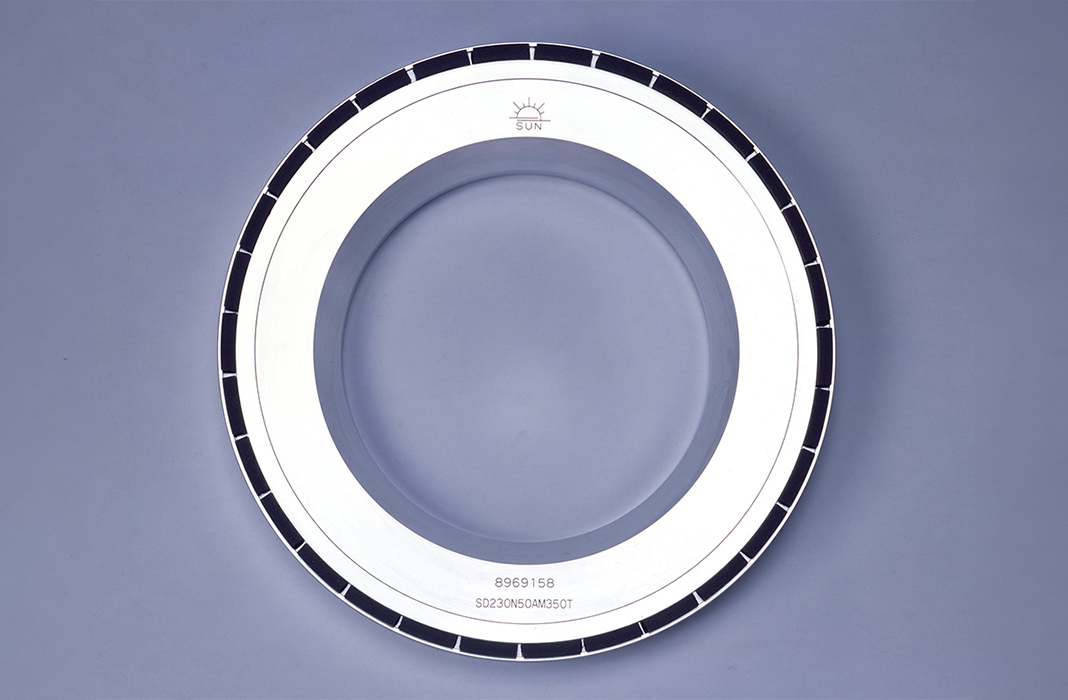

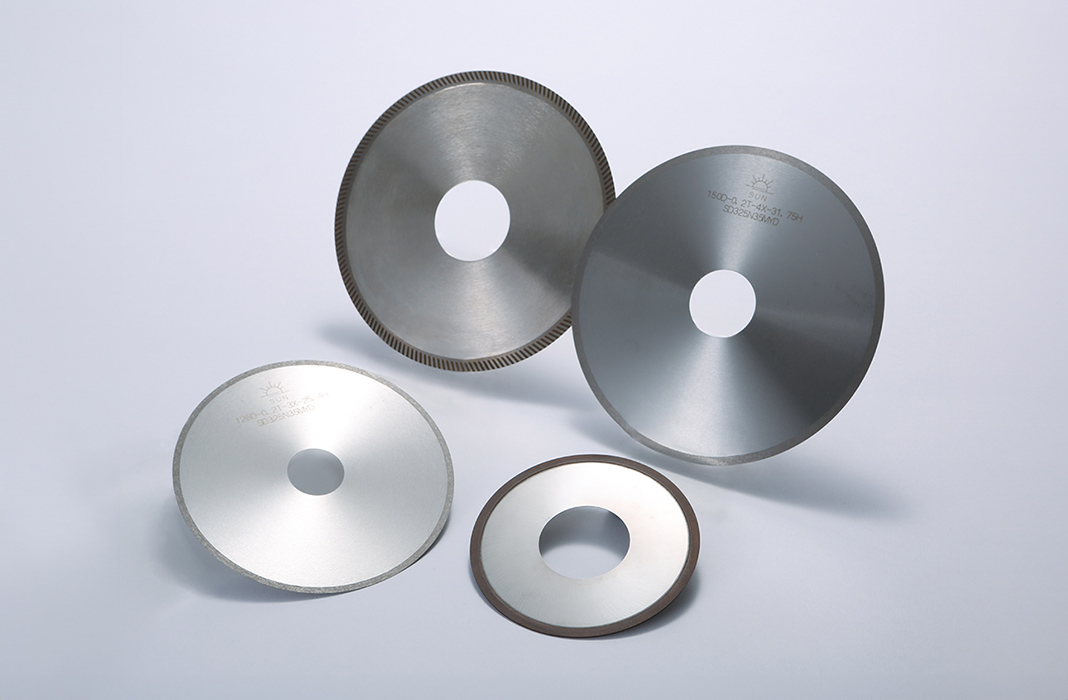

Dicing Blade

Dicing blades are available in "hub type" and "ring type." The hub type is mainly used for dicing silicon and compound wafers for semiconductors. The hub type is mainly used for dicing silicon and compound wafers for semiconductors. The aluminum base and nickel diamond layer are combined into a single unit, making it easy to handle. The ring type can be used for a wide range of cutting and grooving of various PKG and electronic component materials in addition to semiconductor silicon and compound wafers. Three types of bond can be selected: electroformed, metal, and resin. The electroformed bond can produce an ultra-thin blade with a thickness of 15 μm. The resin bond is often used for cutting glass, ceramics, QFN, and other PKGs where chipping and cutting resistance must be suppressed. Metal bond can be selected from a wide range of bond lineups, from high rigidity types comparable to electroforming to types with excellent cutting performance, to suit various work materials.