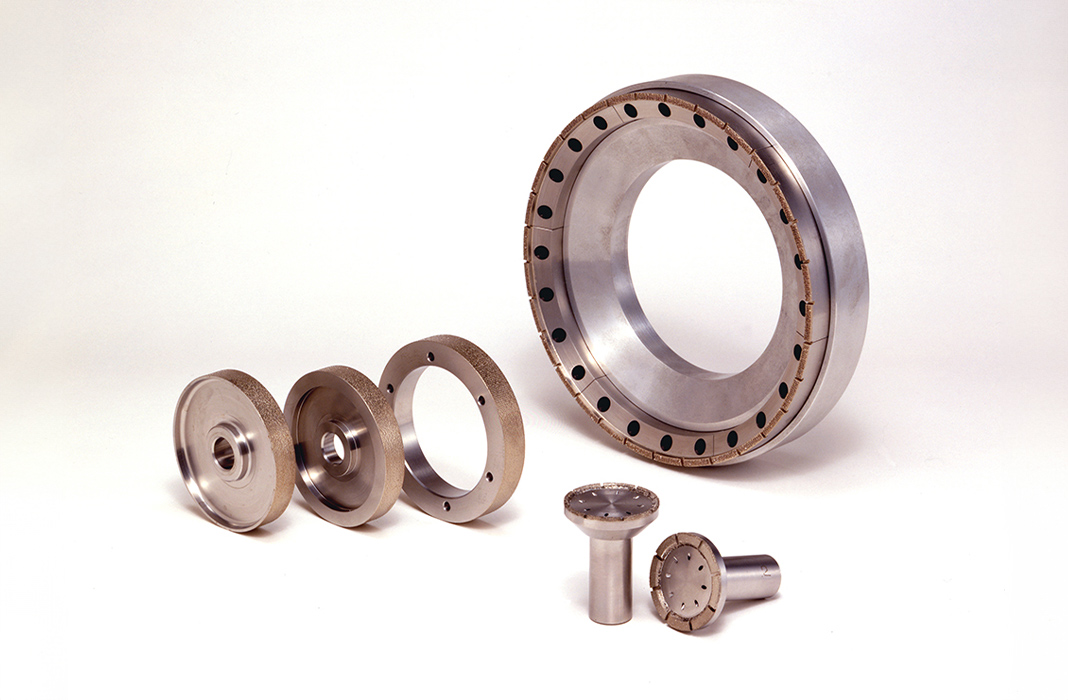

Brazed Diamond Tools "STAR LAYER"

Brazed Diamond Tools "STAR LAYER" (Our registered trademark name: STAR LAYER) are tools that have a structure ㏌ which diamond abrasive grains are fixed ㏌ a single layer on a precisely machined base metal using brazing material. In contrast to electroplated tools, the abrasive grains are firmly bonded to the base metal, giving them strong retention strength and a large protrusion. In addition, the arrangement and spacing of the abrasive grains can be adjusted, and by taking advantage of the improved sharpness and the characteristics of being less prone to clogging, it can be used for a variety of applications and tool shapes (Diamond Core Drills, Diamond Cutters, Diamond Wheels, etc.) from rough processing to finishing processing.

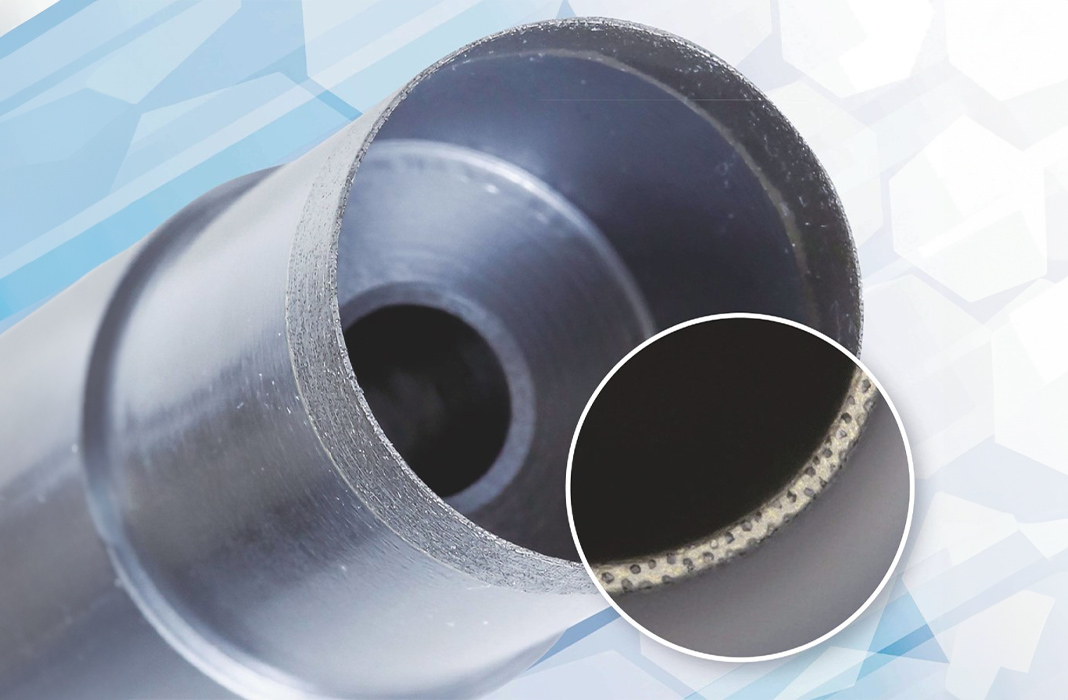

Abrasive Grain Uniform Dispersion Metal Wheel "SOLOTEL"

In the machining of precision parts and mechanical parts made of ceramics and other materials, the technology of uniformly dispersing abrasive grains in the abrasive grain layer has made it possible to improve sharpness while maintaining a long service life, compared to conventional metal tools.

In addition, the ultra-thin abrasive grain layer reduces machining load and chipping in the machining of hard and brittle materials and other special materials, thereby improving machining efficiency and demonstrating its superiority over other tools.

In addition, the ultra-thin abrasive grain layer reduces machining load and chipping in the machining of hard and brittle materials and other special materials, thereby improving machining efficiency and demonstrating its superiority over other tools.

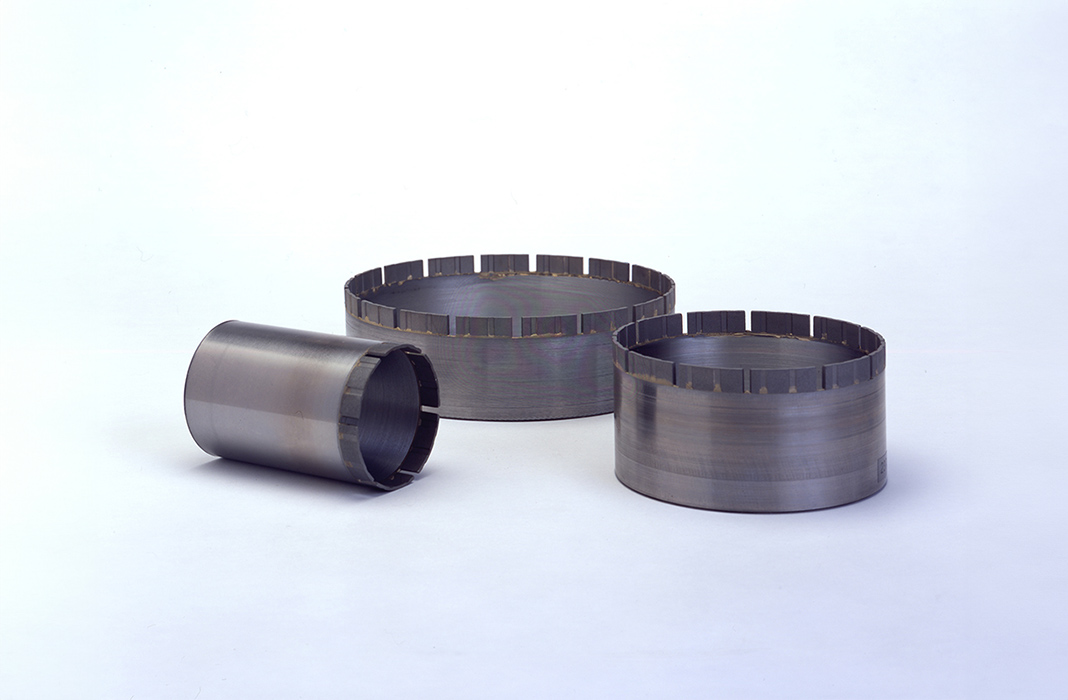

Mining Bits

These tools are used for drilling boreholes to investigate mineral resources and hot springs, drilling holes for injecting ground reinforcement agents in dam and tunnel construction, and checking the foundation ground in civil engineering works.

Thin-Wall Bits

Used for drilling holes for heating and cooling, electricity, and water works in concrete structures, demolition work by continuous drilling (line-cut method), and earthquake-resistant reinforcement work. M27" and "HYPERMALL MEGA (A-lot thread)" for single-point structures, and "HYPERMALL Z (wet)" and "HYPERMALL DRY (dry)" for three-point structures are available in our standard stock.

Core Drills for Automotive Glass Drilling

This core drill is used for drilling holes in automotive glass, which plays an important role in improving automobile safety. It is equipped with a seamer section that drills holes and performs chamfering at the same time.

Precision Core Drills

Core drill with excellent accuracy and sharpness, suitable for various work materials such as LED substrate materials, semiconductor materials such as sapphire, ceramics, etc.