Gear Dressers

This is a special gear-shaped dresser used for dressing worm-shaped grinding wheels for gear grinding and dressing internal gear-shaped grinding wheels for fine finishing, and is effective for mass production of high-precision gears.

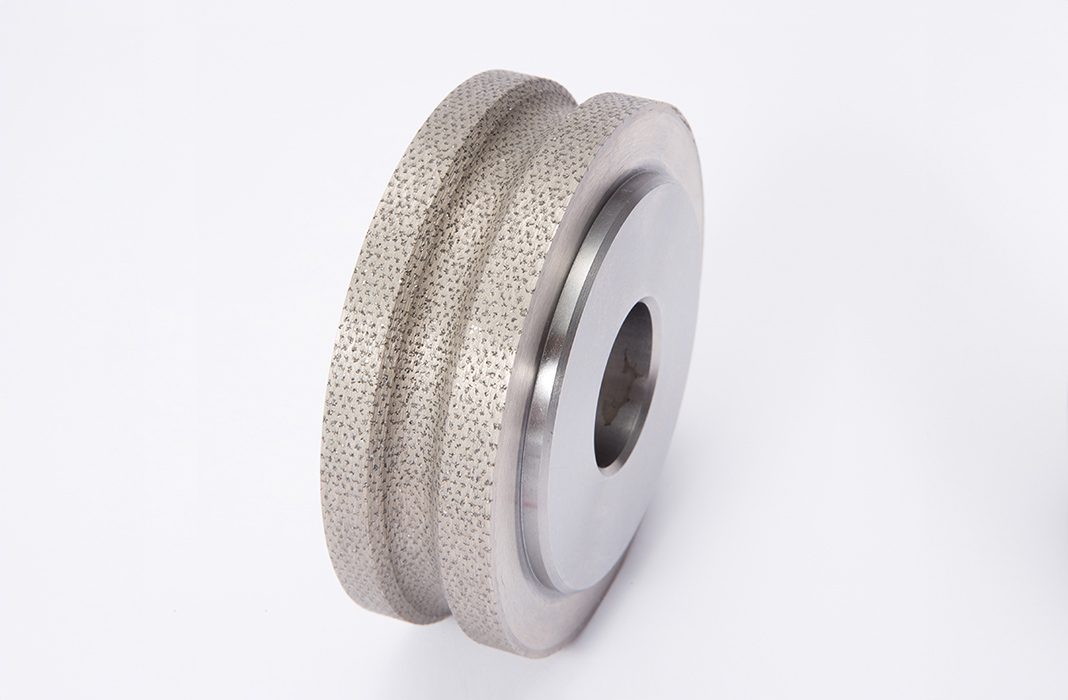

Sintered Spiral Dressers

Sintered roller dresser with excellent dressability and formability. It is especially effective in shaping hard grinding wheels. The diamonds are set in a spiral shape, which widens the grain spacing in the circumferential direction and improves sharpness, and the grain spacing in the width direction is narrower, enabling uniform shaping of the grinding wheel. As a result, highly efficient and precise grinding is now possible.

Prisma Dressers

Instead of granular diamonds, this dresser has one or more columnar diamonds embedded. Since the contact area remains the same from the initial dressing stage to life-out and stable dressing performance is achieved, automated lines and multiple dressers are best suited for large-diameter grinding wheels. In addition, the feed rate can be increased compared to that of a single point dresser, thus reducing dressing time. Diamond size can be selected according to the type and dimensions of the grinding wheel.

Diamond Dresser "Natural Edge"

This is a single-point dresser with a pyramid-shaped cutting edge generated at the tip by grinding. Compared to conventional natural rough diamond dressers, this dresser provides more stable cutting performance and can work under similar dressing conditions. This dresser specializes in cutting performance and is good at grinding wheels with high elasticity like rubber grinding wheels.

Natural Diamond Dressers

Natural diamond dressers are dressers with one or more diamonds sinter mounted on the tip of the shank. The truing and dressing capabilities of the dresser have a significant impact on grinding efficiency and finishing accuracy. Various dressers are available to meet the various needs of customers in wheel shaping.

Synthetic Single Crystal Diamond Single-Point Dressers "SUTABULU"

This is a single-point dresser with a conical cutting edge generated at the diamond tip by grinding. Compared to existing natural rough diamond dressers, this dresser provides more stable cutting performance and can work under similar dressing conditions. In addition to basic dressing performance, this dresser excels in simple shape modification such as R shape and tapered shape, and is highly versatile.

Electroformed Roller Dresser with Sharpness-focused "iSTroll"

Electroformed roller dresser with diamond grains regularly arranged to reduce grain concentration and improve sharpness. Grain concentration can be adjusted according to your needs. The sharpness of parts requiring complex shapes can be controlled.

Electroformed Roller Dresser for Specialized Performance in Sharpness "KD Dresser"

In addition to the iSTroll, which has been well-received in machining requiring excellent cutting performance, the newly developed KD Dresser boasts cutting performance that exceeds that of the iSTroll. It is an electroformed roller dresser of a high precision total type with a high cutting ability and an abrasive grain array type roller dresser.

Roller Dresser with Short Delivery "SA Dresser"

We support customers' prototype development with short delivery times that exceed conventional common sense. This roller dresser, a high-precision general-purpose type, achieves quick delivery while maintaining the performance of conventional products. This roller dresser is designed to meet the needs of those in charge of prototype development, etc., who place priority on quick delivery.

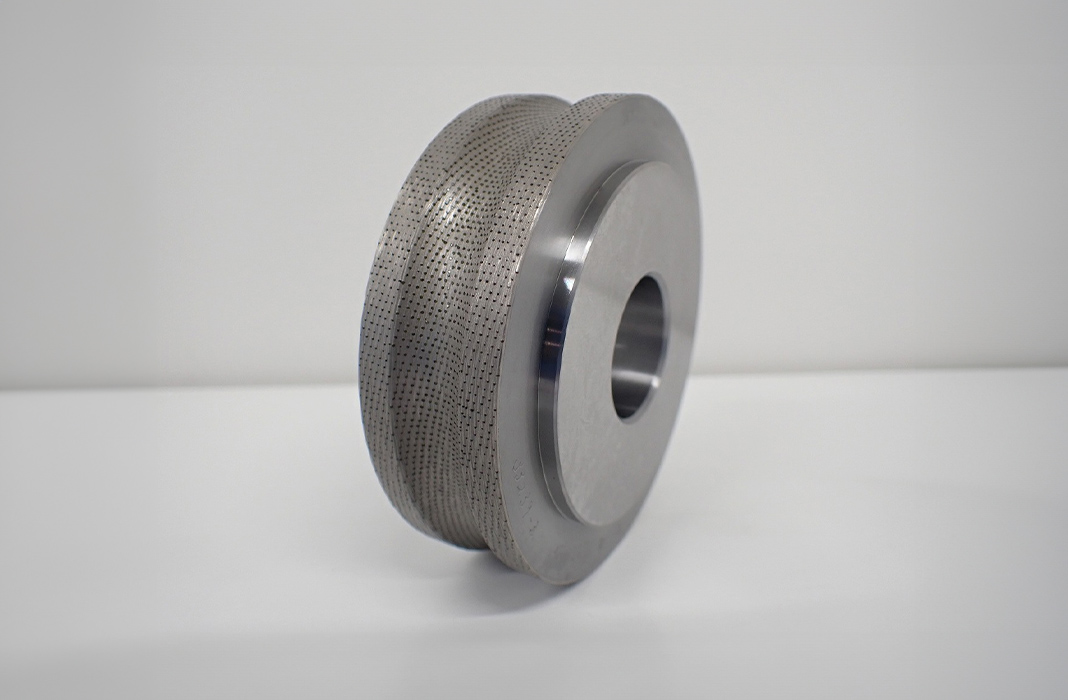

Roller Dressers

Diamond roller dressers are used for forming and dressing fired abrasive grinding wheels and CBN wheels. Since these dressers are capable of accurate and speedy form dressing, they can effectively be used to mass produce work parts with a high degree of accuracy. Diamond roller dressers are available in sintered and electroforming types.

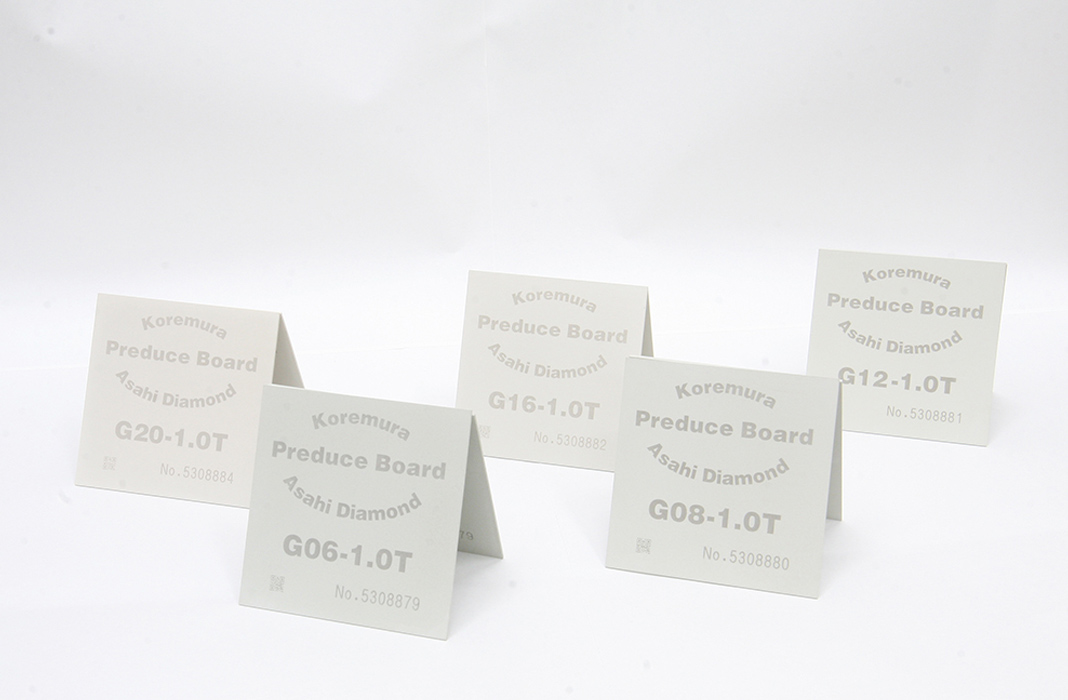

Koremura Asahi Products Dressing plate "Preduce board"

Vitrified grinding wheel using general abrasive grains. A wide variety of wheel configurations from soft to hard are possible, and they are effective as dressing materials for metal tools.