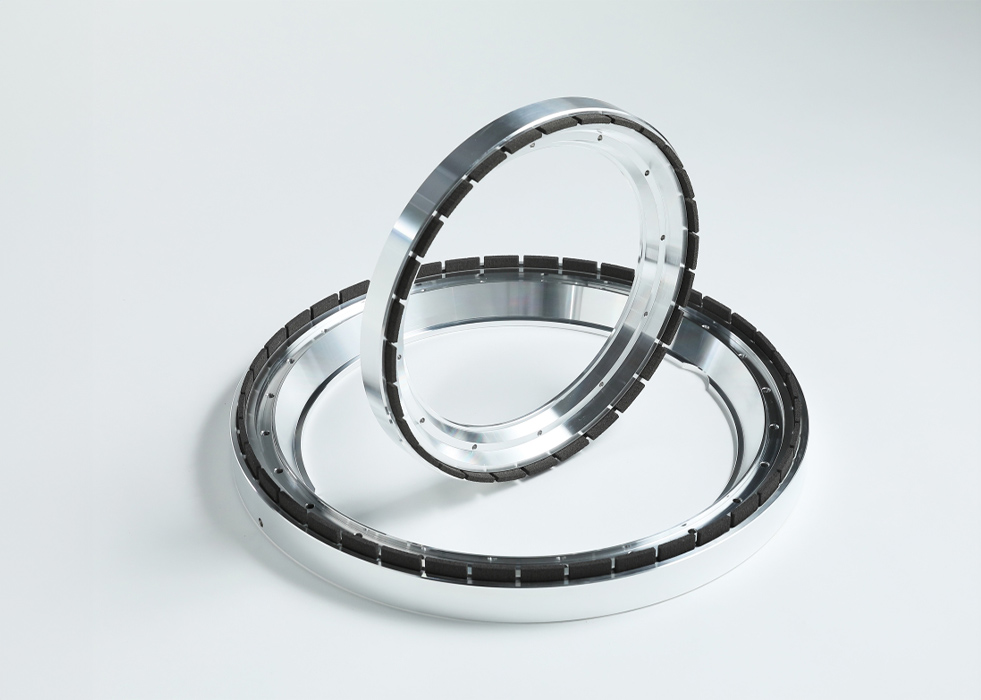

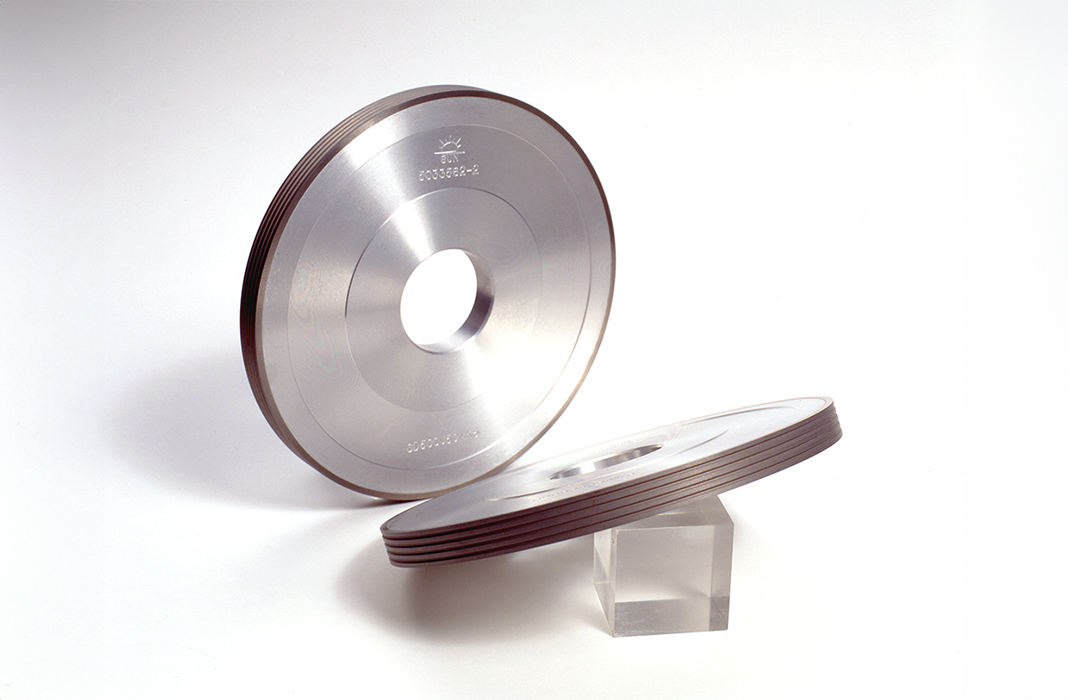

Super porous metal bonded grinding wheel "M-cloud"

Metal bond wheels for surface grinding of wafers such as SiC and GaN. The ultra-porous structure realizes fine grain grinding, which could not be applied with conventional metal bond wheels, and has excellent sharpness and wear resistance compared to vitrified bond wheels of the same particle size.

"SUN CREST 2" Electroplated Wheels

Electroplated wheels are equipped with thread-like irregularities on the outer circumferential surface and are specialized for processing that requires sharpness.

Compatible with difficult-to-cut materials High-efficiency metal bond "SUNCREA"

SUNCREA contributes to improving processing efficiency and reducing costs in hard and brittle materials such as sapphire, carbide, and ceramics, hard magnetic materials such as ferrite and neodymium iron, and iron-based materials such as sintered parts.

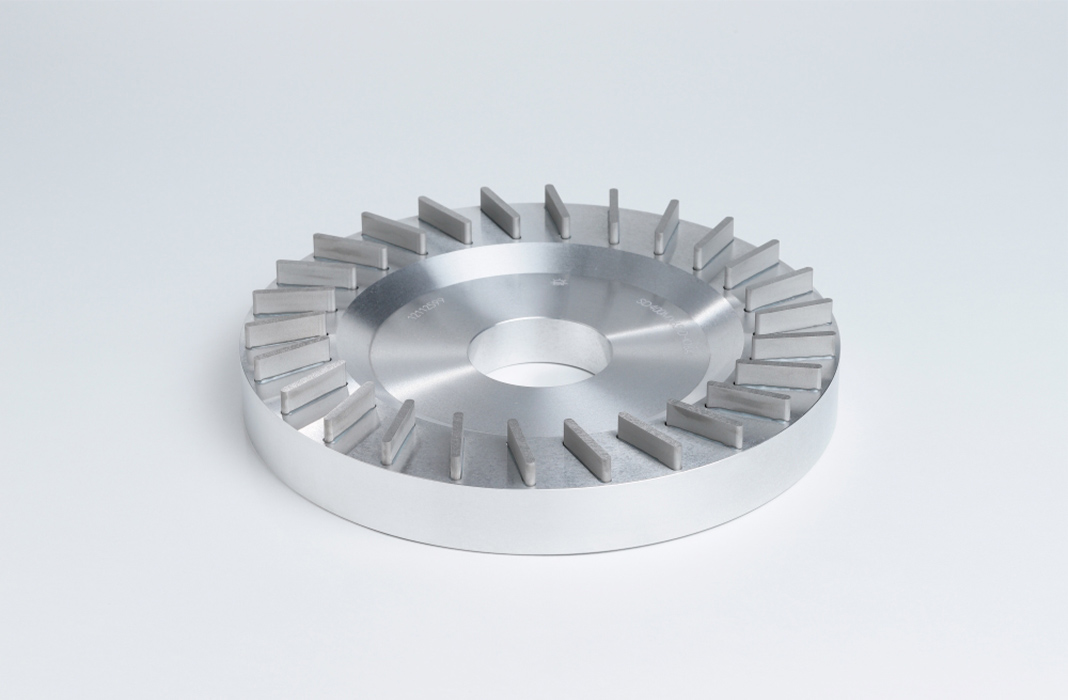

"AEROMETAL" Super-Porous Metal Bond Wheels

Features

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with electrodeposition truer is possible (limited to CBN ).

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with electrodeposition truer is possible (limited to CBN ).

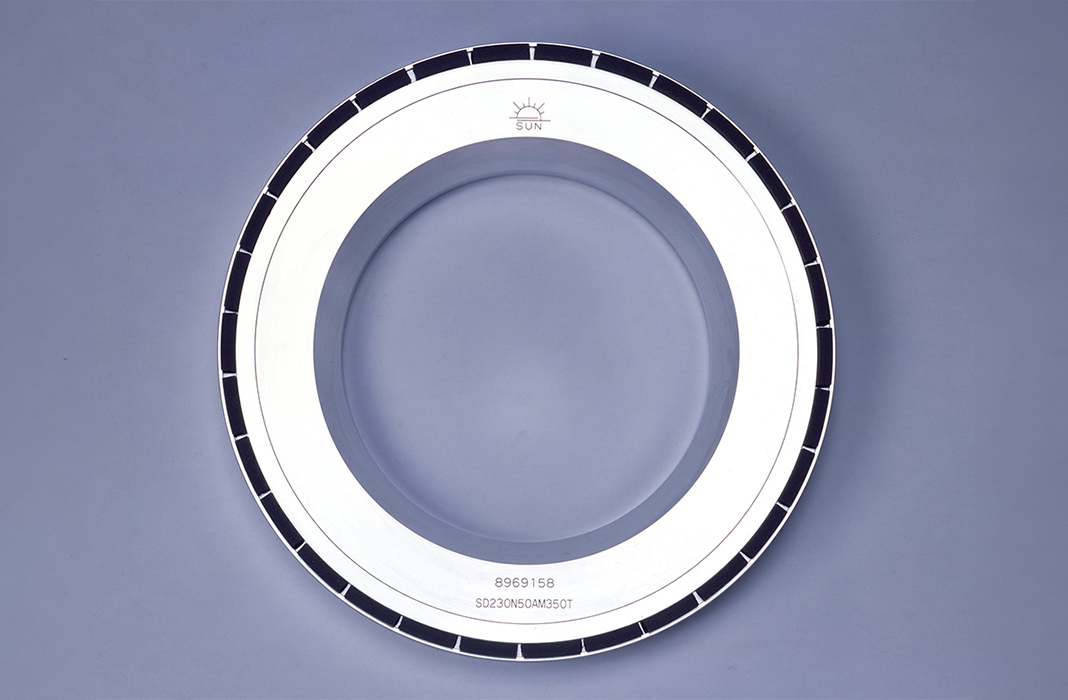

Diamond metal bond wheels (for automobile glass chamfering)

Diamond metal wheels for beveling automobile glass, which play an important role in improving automobile safety.

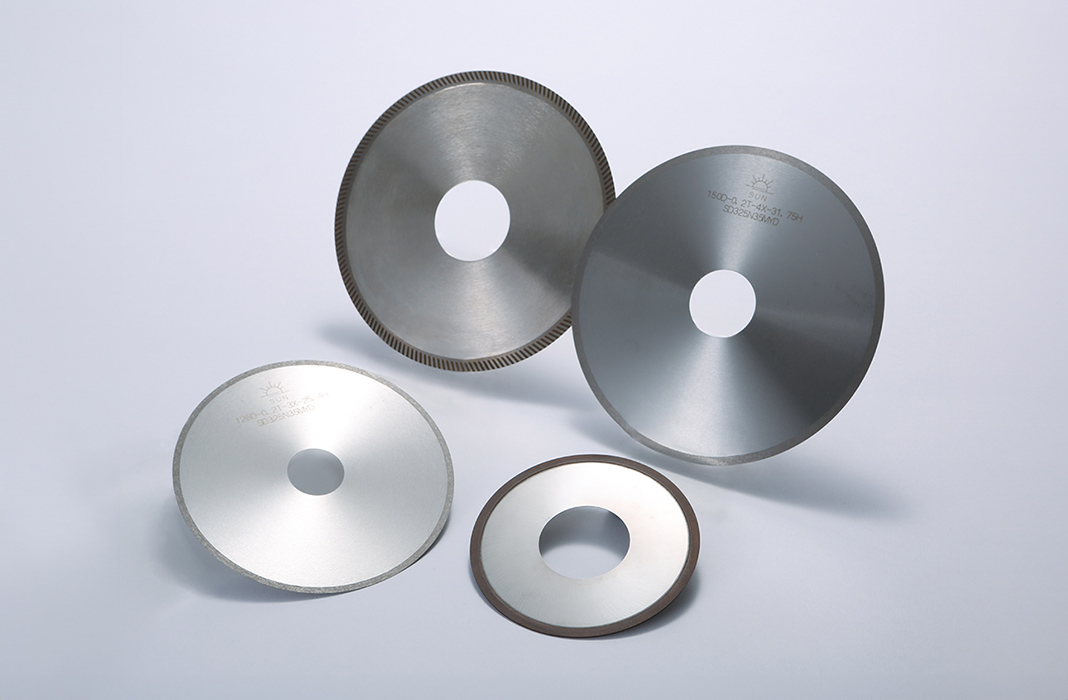

Diamond Wheel (for Optical Glass, Precision Grinding)

Diamond wheels are an indispensable tool for processing lenses for cameras and binoculars, prisms, and, more recently, glass substrates for hard disks. Depending on the processing purpose, there are pellets, curve generators, coring and chamfering wheels, etc. In addition, these types of bonds such as metal, resin, polyx, and electrodeposition each have high performance.

Thin glass chamfering wheel

This wheel is used for chamfering thin glass used in displays such as TVs, PCs, and smartphones.

"SOLOTEL" abrasive grain uniform dispersion metal grinding wheel

In the machining of precision parts and mechanical parts made of ceramics and other materials, the technology of uniformly dispersing abrasive grains in the abrasive grain layer has made it possible to improve sharpness while maintaining a long service life, compared to conventional metal tools.

In addition, the ultra-thin abrasive grain layer reduces machining load and chipping in the machining of hard and brittle materials and other special materials, thereby improving machining efficiency and demonstrating its superiority over other tools.

In addition, the ultra-thin abrasive grain layer reduces machining load and chipping in the machining of hard and brittle materials and other special materials, thereby improving machining efficiency and demonstrating its superiority over other tools.

High elasticity resin wheel "Bright Star"

Bright Star is a superabrasive wheel with a special bond structure that has a high elasticity not found in conventional resin bonds, and is effective for processing that requires luster. BRS5 bond is a soft type and is effective for polishing processes such as lapping and polishing.

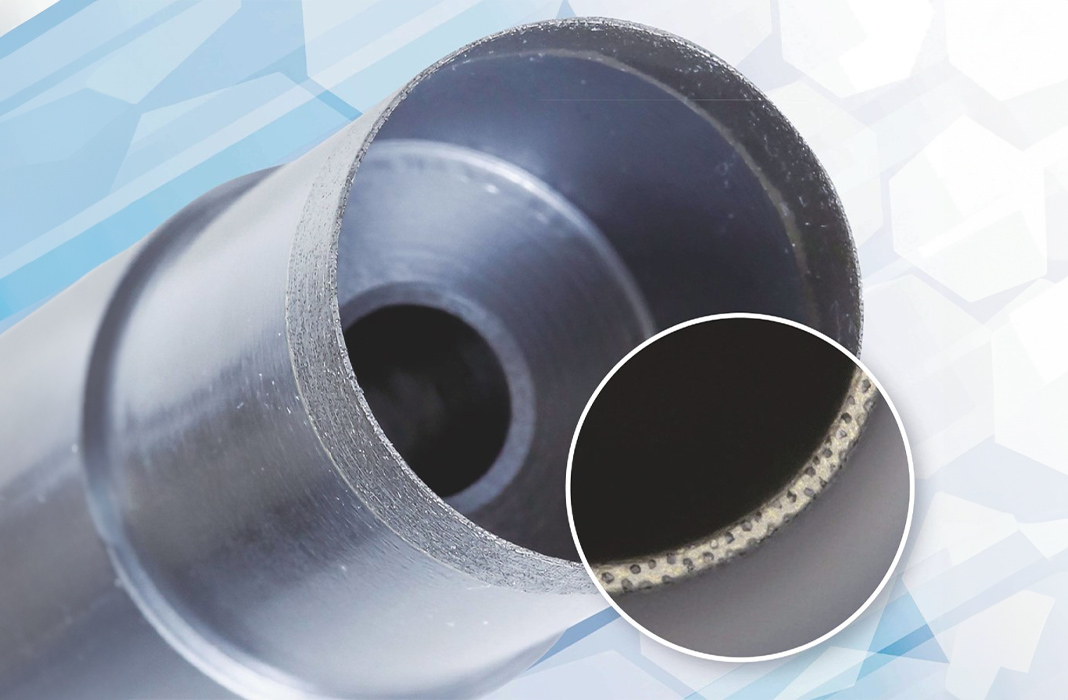

Core drill for automotive glass drilling

This core drill is used for drilling holes in automotive glass, which plays an important role in improving automobile safety. It is equipped with a seamer section that drills holes and performs chamfering at the same time.

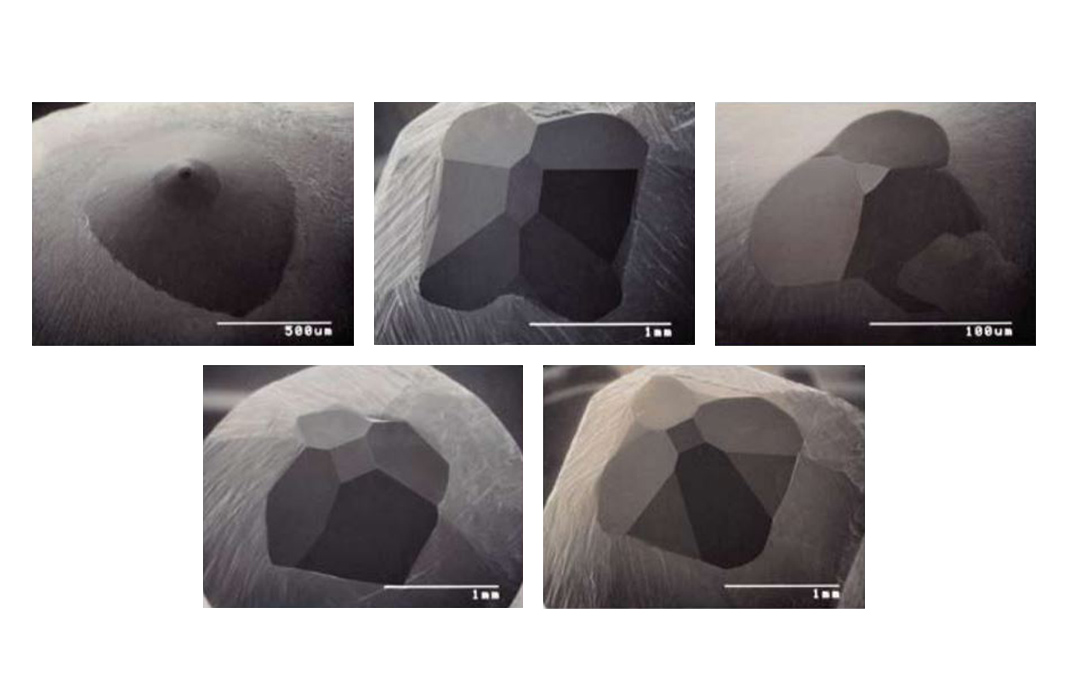

Diamond Scriber

This tool is used for cutting hard and brittle materials such as compound semiconductors (gallium arsenide, gallium phosphide) and sapphire. There are also types in which rough diamonds are processed into a conical shape (1-point) or 2-, 3-, 4-, or 8-point cutting edges, depending on the application. Since grinding water is not used, treatment facilities are not necessary, and the narrow scribe line allows a large "chip count" to be obtained. Chipping during breaking is less likely to occur than when using a cutter, and the optimum "point" shape can be selected.

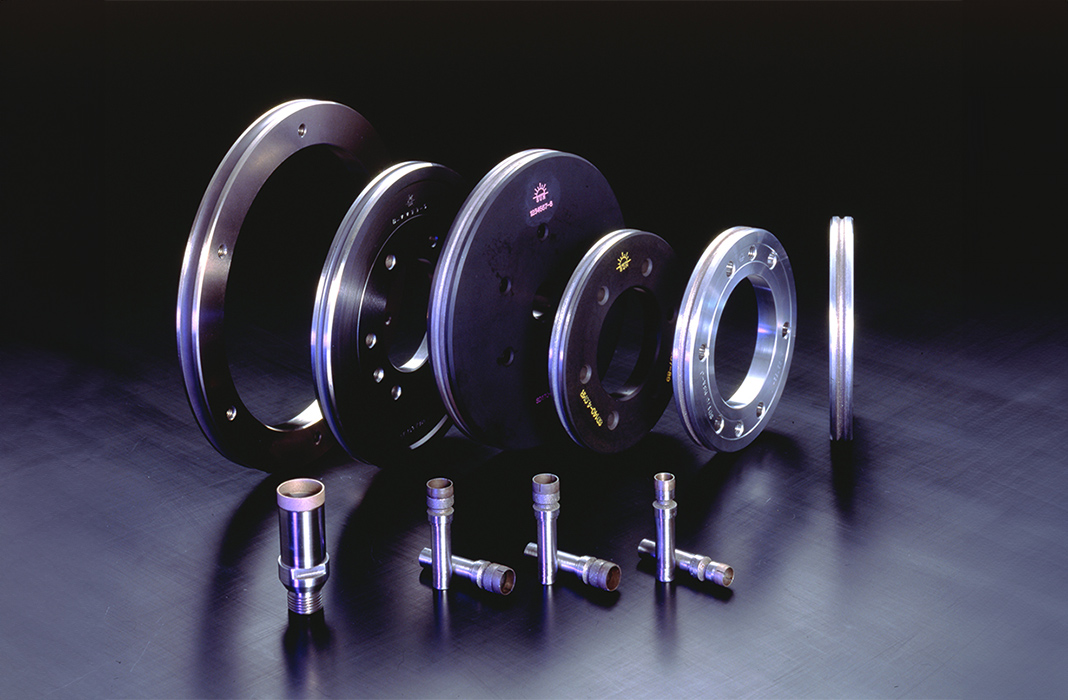

Cutter with base metal

Cutters with a metal base are available in "multi-cutters" and "single-blade types. Multi-cutters can cut and groove by combining multiple cutters with specifications suitable for the work material. Our unique technologies such as cutting edge shape, pitch accuracy, and accumulation accuracy realize high machining quality. The single-blade type is a cutter with a diamond or CBN abrasive grain layer formed on the periphery of the steel base metal. Electrodeposition, metal, or resin can be selected for the bond, and the cutting edge shape (V-shape, R-shape) and base metal shape (all nipples, under neck nipple) can also be selected according to requirements.