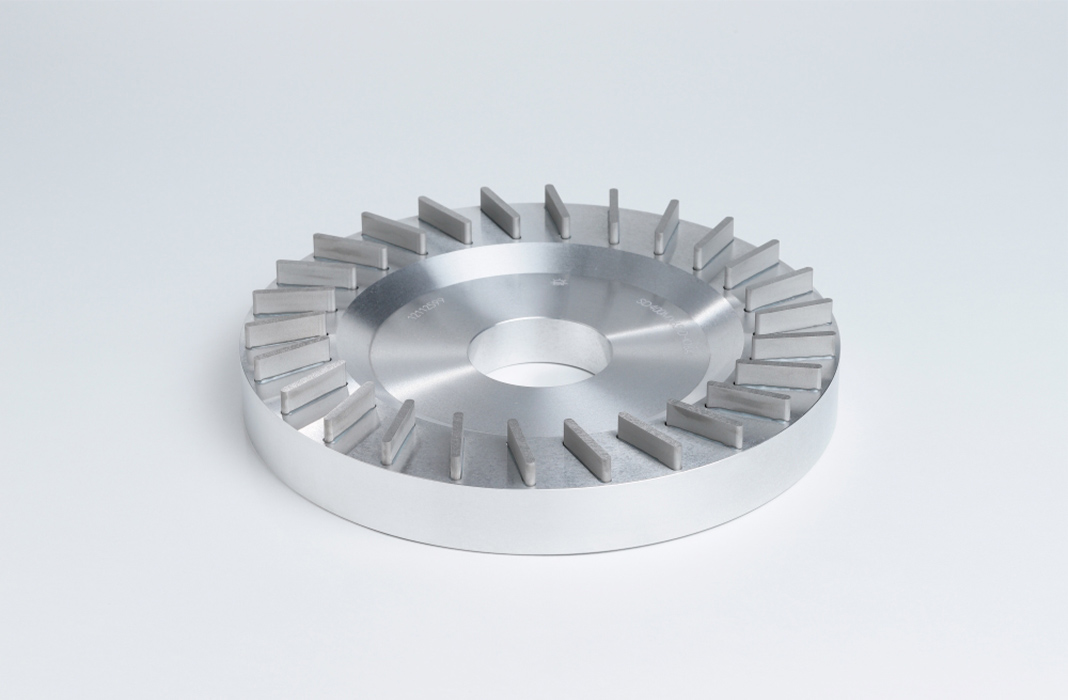

Array Grain Electroplated Wheels "AG Wheel"

AG(Array Grain) wheel.

The outstanding sharpness prevents clogging and burn mark, and the service life is more than twice as long as that of conventional Electroplated. It can be used for profile type and is effective in a wide range of machining operations from roughing to finishing.

The outstanding sharpness prevents clogging and burn mark, and the service life is more than twice as long as that of conventional Electroplated. It can be used for profile type and is effective in a wide range of machining operations from roughing to finishing.

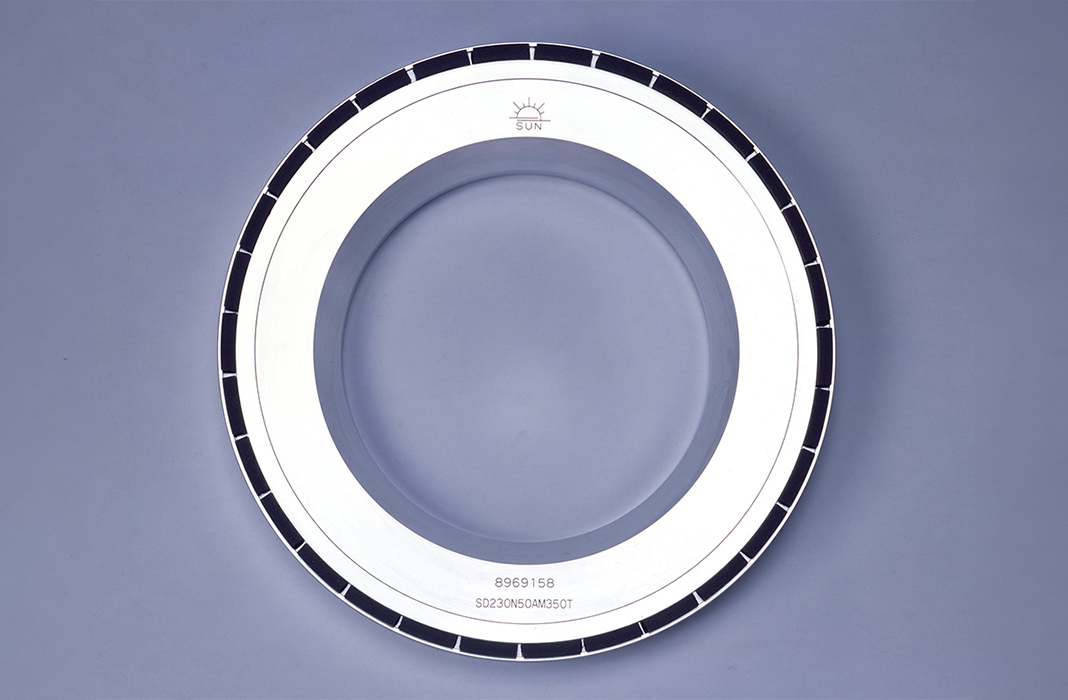

High-efficiency Metal Bond for Difficult-to-cut Materials "SUNCREA"

SUNCREA contributes to improving processing efficiency and reducing costs in hard and brittle materials such as sapphire, carbide, and ceramics, hard magnetic materials such as ferrite and neodymium iron, and iron-based materials such as sintered parts.

Super-Porous Metal Bond Wheels "AEROMETAL"

Features

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with Electroplated truer is possible (limited to CBN ).

1) Good chip evacuation

(2) Stable grindability

(3) Excellent wear resistance and long life

(4) Truing with Electroplated truer is possible (limited to CBN ).

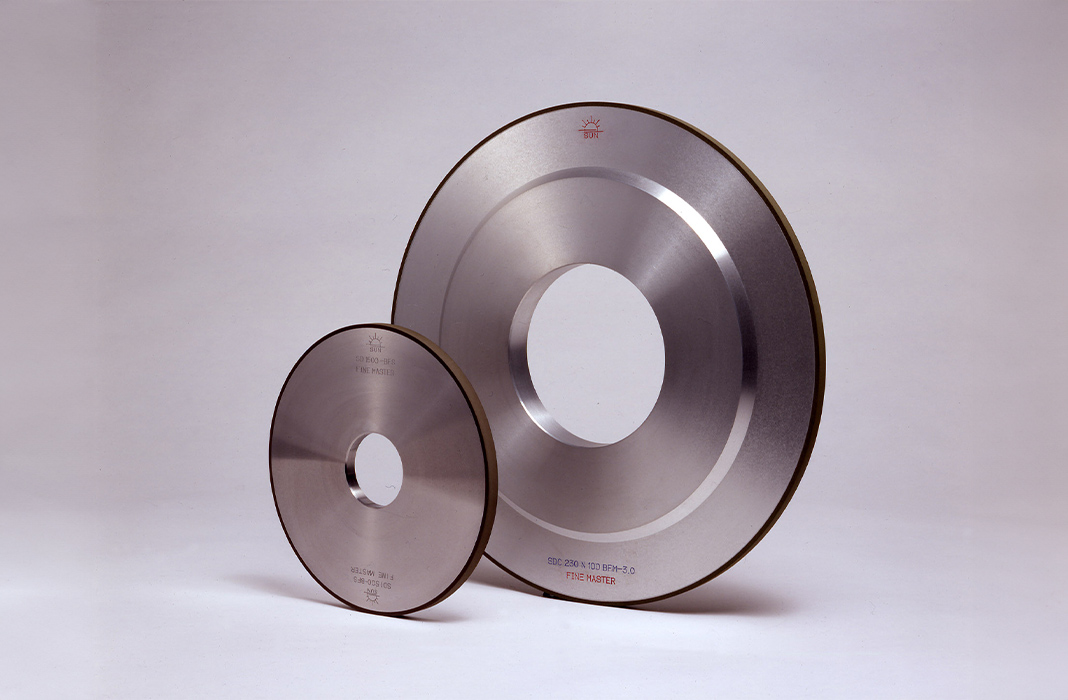

Simultaneous Grinding & Mirror Fishing "FINE MASTER"

The FINE MASTER series is a wheel that uses "BFM bond" for simultaneous grinding that realizes simultaneous grinding of heterogeneous composite materials such as tungsten carbide and steel materials with high efficiency and high precision, and "BFS bond" for mirror finishing, which realizes mirror grinding of tungsten carbide, steel materials, ceramics, etc. with high efficiency and high precision.

Double Disc Centerless Grinding Wheels "TafRa"

TafRa wheels are Products with higher abrasive grain retention compared to exciting products. In Double disc grinding and centerless grinding, where the spontaneous action of abrasive grains is unlikely to occur, The abrasive grains remain for a long time without falling off, so that the sharpness is maintained and the dress interval is extended. As with existing products, it can be applications with WA dresses and X-POWER dresses.

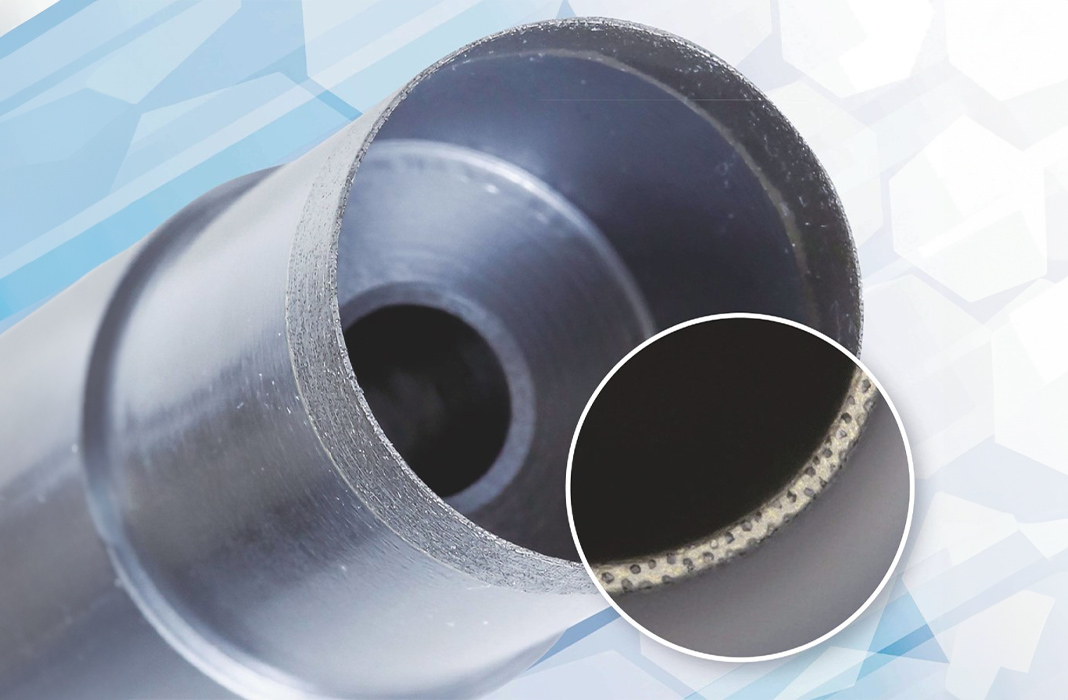

Electroplated Reamer (for one-pass honing)

High-precision electroplated reamer with micron-level control of tool outer diameter accuracy and good machining accuracy.

Using a machining center that does not require a dedicated machine, high-efficiency is achieved by one-pass processing.

Using a machining center that does not require a dedicated machine, high-efficiency is achieved by one-pass processing.

Abrasive Grain Uniform Dispersion Metal Wheel "SOLOTEL"

In the machining of precision parts and mechanical parts made of ceramics and other materials, the technology of uniformly dispersing abrasive grains in the abrasive grain layer has made it possible to improve sharpness while maintaining a long service life, compared to conventional metal tools.

In addition, the ultra-thin abrasive grain layer reduces machining load and chipping in the machining of hard and brittle materials and other special materials, thereby improving machining efficiency and demonstrating its superiority over other tools.

In addition, the ultra-thin abrasive grain layer reduces machining load and chipping in the machining of hard and brittle materials and other special materials, thereby improving machining efficiency and demonstrating its superiority over other tools.

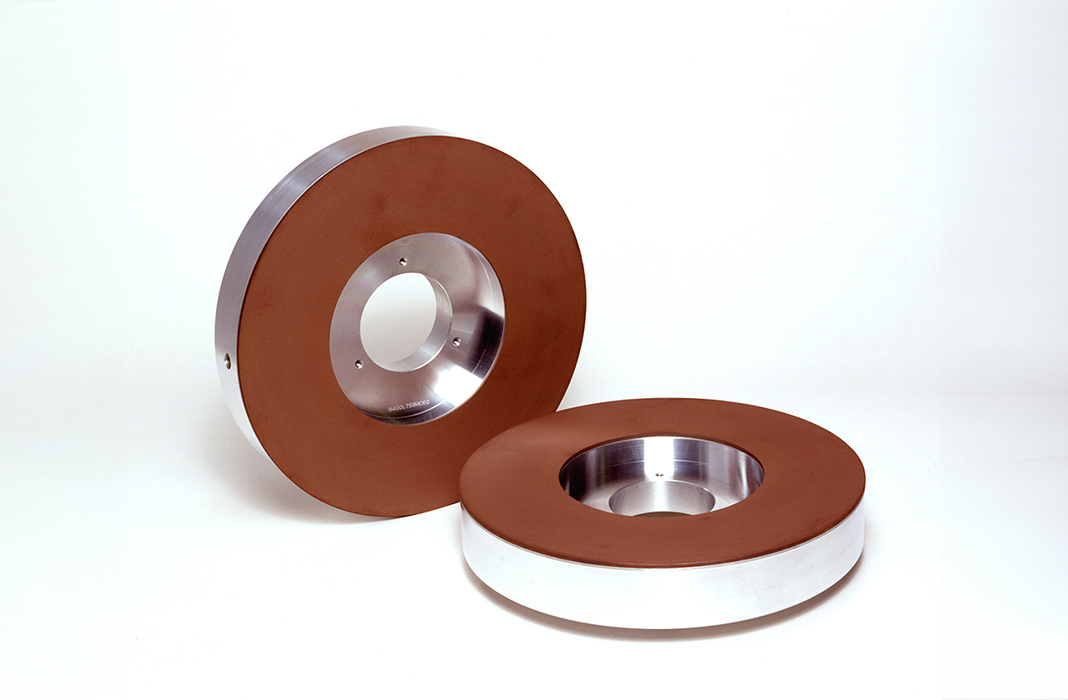

High Elastic Resin Bond Wheel "BRIGHT STAR"

Bright Star is a superabrasive wheel with a special bond structure that has a high elasticity not found in conventional resin bonds, and is effective for processing that requires luster. BRS2 Bond is a hard type that is effective for processes that require a certain amount of material to be removed, and is compatible with both lapping and grinding. BRS5 bond is a soft type and is effective for polishing processes such as lapping and polishing.

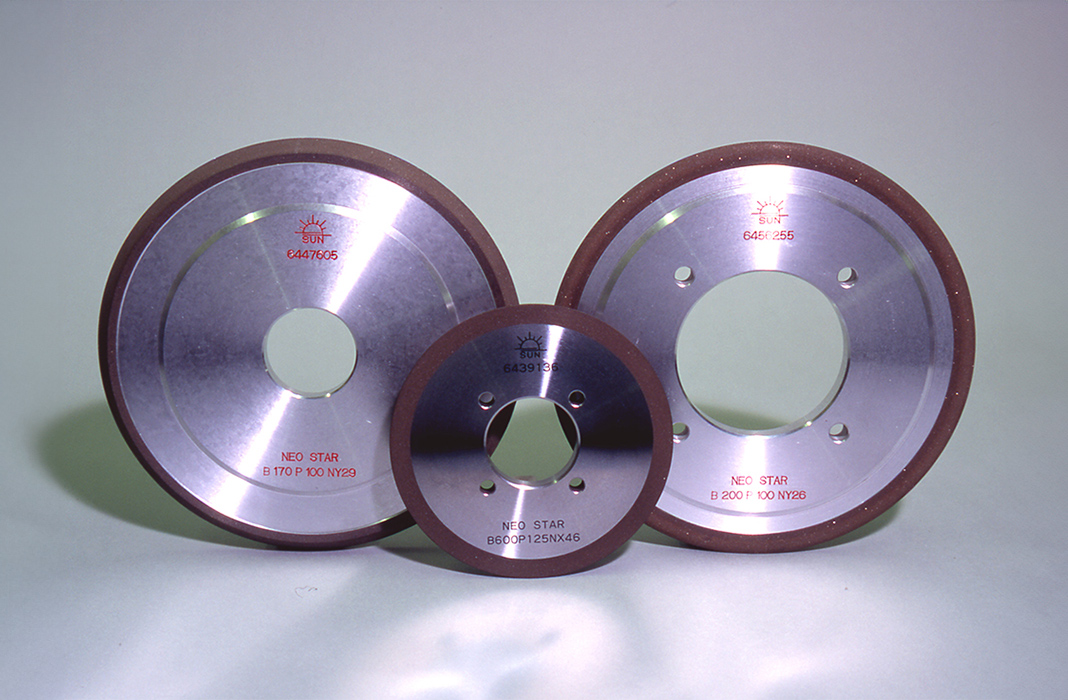

CBN POLYX Wheel for Ferrous Materials "NEO STAR"

NEO STAR wheels are bonded with polyimide resin, which has excellent heat resistance, tensile strength, and elasticity. It can be used for grinding that requires long-time shape retention, heavy-duty grinding, creep-feed grinding, efficient grinding of high-hardness steel (HRC67 higher), and grinding of relatively low-hardness steel (HRC40-50 ) that requires long life.

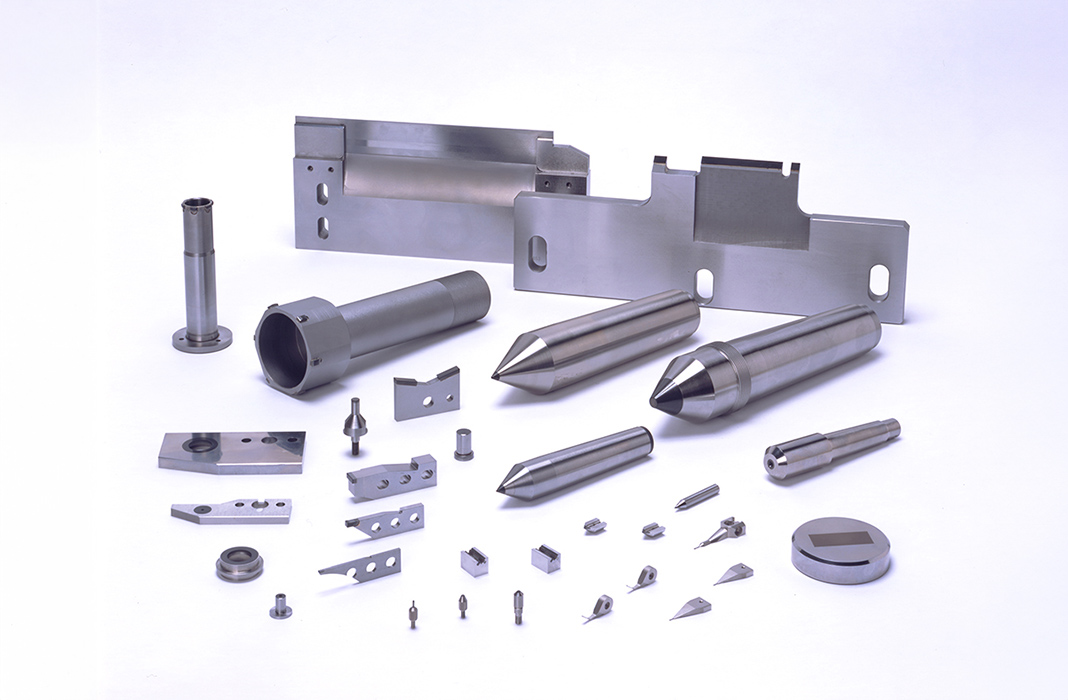

SUNPAX Wear Resistant Tools

Lace centers (concave/convex): Sampax is used on the tips of concave/convex centers that support workpieces on lathes and grinders to achieve long-term, high-precision machining.

Centerless blades: SUNPAX is used in the blade wear area of centerless grinding machines to achieve high-precision, high-efficiency machining.

Shoes and rests: Wear resistance is especially required for the parts that hold the workpiece in place on the grinding machine. The use of "Sampax" for this purpose makes it possible to maintain high machining accuracy.

Measuring tools: When measuring the dimensions of machined parts, the use of diamonds or Sampax on the tips of measuring tools provides resistance to abrasion and helps maintain measurement accuracy.

Centerless blades: SUNPAX is used in the blade wear area of centerless grinding machines to achieve high-precision, high-efficiency machining.

Shoes and rests: Wear resistance is especially required for the parts that hold the workpiece in place on the grinding machine. The use of "Sampax" for this purpose makes it possible to maintain high machining accuracy.

Measuring tools: When measuring the dimensions of machined parts, the use of diamonds or Sampax on the tips of measuring tools provides resistance to abrasion and helps maintain measurement accuracy.

Diamond Coated Tools

Our original coating technologies utilizing the chemical vapor deposition method can be applied on tools with any complicated shape while retraining both high adhesiveness to base metal and excellent wear resistance. With choice of the right type and thickness of coating depending on the application, these tools are most suitable for processing carbon, ceramics, and FRP.

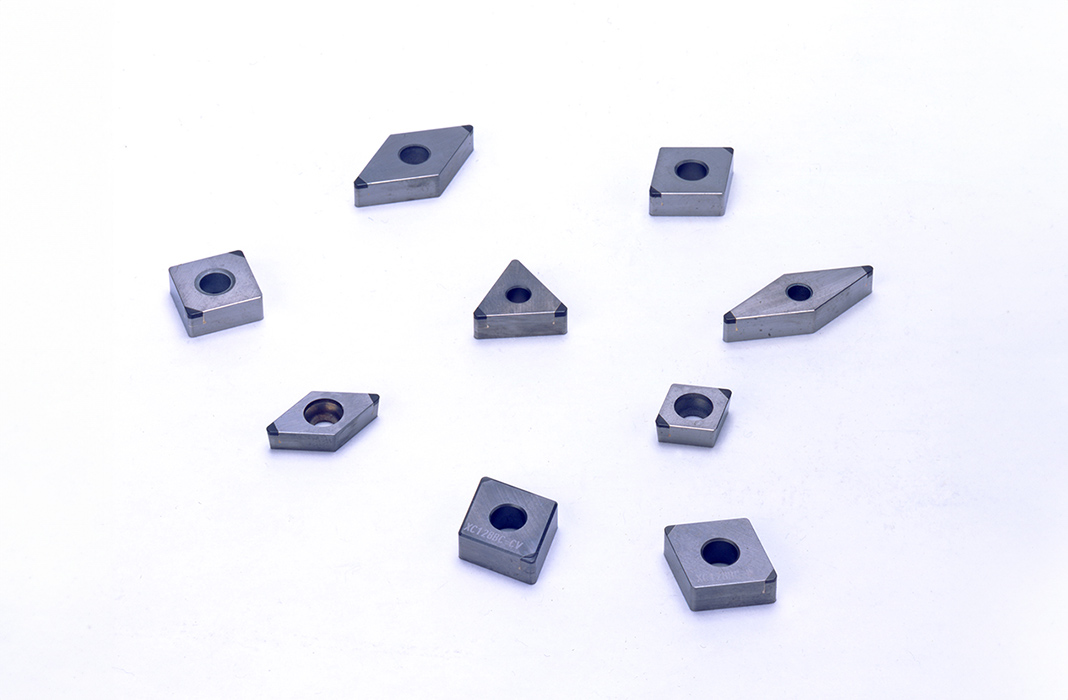

PCBN Insert "SUNNITE TWIN"

One-use type for ferrous materials (no regrinding)CBN tip replacement tip "SUNNITE TWIN" for ferrous materials. It is highly economical, and the two-cornerCBN cutting tool cost can be reduced because of the two-corner CBN cutting edge.